Jet Fire Resistance (Integrity Only)

The New Generation seal system has been tested against Jet fire to ISO-22899-2 standard. The seals are tested in a true bulkhead orientation rather than the regimented tubular design of earlier standards. This latest standard allows clear line of sight to the rear of the seals and visual proof of conformance while testing.

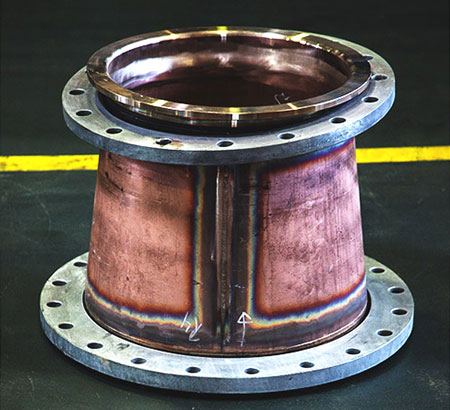

In addition, we have tested a range of seal dimensions from ½” diameter to 36” diameters, as well as elbows for pipe bends and multiple pipe configurations. We successfully tested a six pipe multipipe seal for more than 30 minutes. Twin, single and elbow penetrations for over an hour.

Our certification of approval LR2029555SF is issued by Lloyd’s Register.