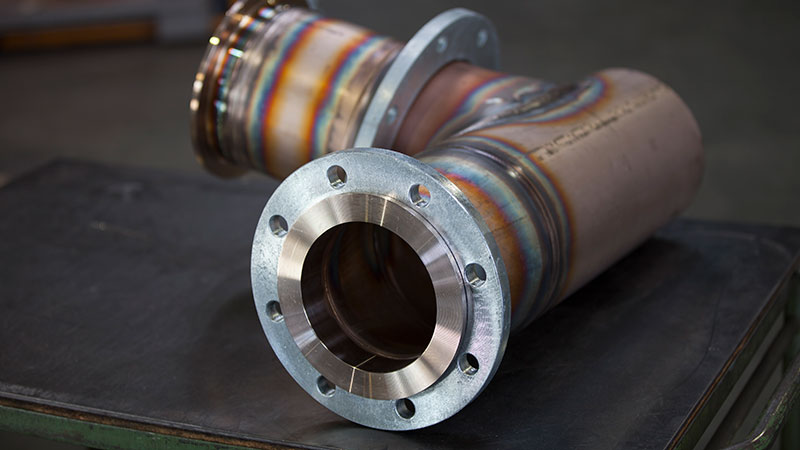

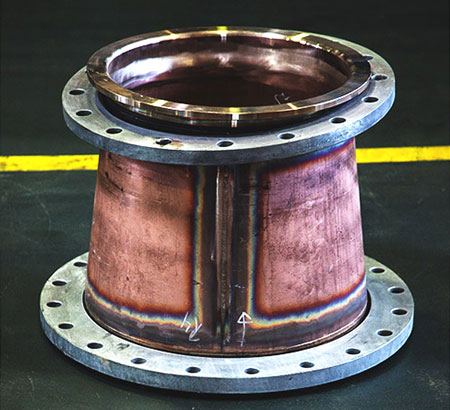

CuNi Pipes & Fittings

Better processing, with long-term durability

CuNi Pipes & fittings are widely used on board FPSO vessels, Modules, Naval vessels & LNG plants. We can supply pipes, concentric reducers, elbows, T-pieces, flanges and sockets.

Copper-nickel alloys are among the most corrosion-resistant copper materials. Our brand name EUCARO 10 is the benchmark for CuNi90/10 alloys.

We have further developed the standard trade material quality of CuNi10Fe1,6Mn with regard to better processing and longer-term durability, to be able to better exploit the advantages of our material. Through the optimisation of the alloy components and the minimisation of impurities such as sulphur or phosphorous, our customers receive tubes, flanges and fittings that are fit-for-purpose.