Ancloz Fire Protection Jackets

Flexible, industry-specific specifications

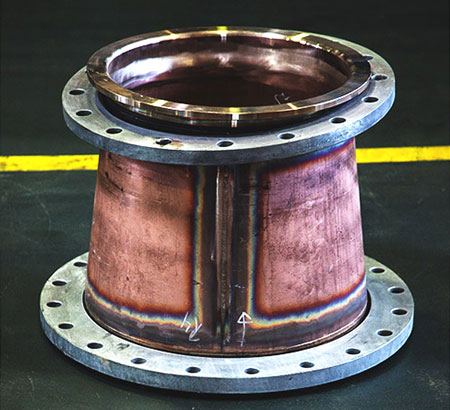

Our three different types of jackets give us the flexibility and range to serve our customers’ protection needs and specifications in a large variety of markets, from Oil and Gas all the way to Nuclear technology. With our versatile products, along with our expertly trained team, we can respond to the specific challenges presented by each individual industry; down to sector-specific requirements including fire type, fire rating/duration and the internal/operating temperature of the protected component.

This expertise, coupled with our passion to serve and our commitment to protect, has enabled us to achieve a new milestone in flexible and removable fire jacketing systems.